Aiya manufacturing process

Matcha particles of several microns

are produced over a long period of time and effort.

Matcha particles of several microns

are produced over a long period of time and effort.

It has a slightly sweet, unique matcha aroma called “mukiko” and beautiful green tea leaves.

At AIYA Co., Ltd., we turn carefully grown tea leaves into matcha using the traditional milling method that has been handed down over the years.

The tea mills used to create the fine particles are made by artisans using a technique called “medate”, which has been passed down from master to apprentice.

Matcha manufacturing process made using Aiya Co., Ltd.'s “traditional tea mortar manufacturing method”

In early April, new buds sprout on the tea plants. When new buds begin to appear, the entire tea garden is covered with a black cover to block sunlight. By blocking sunlight, the change from theanine, which is an umami ingredient, to tannin, which has an astringent taste, is suppressed, and the aroma becomes a faintly sweet scent unique to matcha, called “cover incense”, which brings out the beautiful green color. After the 88th night, tea picking begins.

The newly picked tea leaves are transported to a rough tea processing factory. By steaming at high temperatures, the activity of fermentation enzymes is stopped and the bright green color can be maintained. After that, the water is slowly removed in a large dryer to make dried tea. This state is called aracha or tencha aracha.

By removing the stems and veins from rough tea, we can use only the nutritious and delicious leaf parts as raw materials. Specifically, the tea leaves are sorted, wind sorted, re-dried, electrically sorted, and color sorted before being refined into tencha.

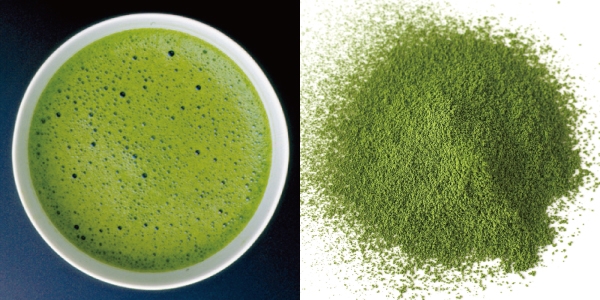

Refined tencha is transported to a matcha factory. In the matcha production room, where humidity and temperature are kept constant, a tea mortar operates 24 hours a day to create matcha of several microns in size. A single tea mortar can produce only 40g of high-quality matcha for tea ceremonies, which is carefully ground in an hour.

After the finished matcha is inspected, it is packaged. Only products that pass inspection will be shipped domestically and around the world while maintaining their freshness.

A tea mortar is an indispensable tool and manufacturing method for producing high-quality matcha. One tea mortar can produce only about 40g of high-grade matcha for tea ceremony, which is several microns in size. Managing the tea mortar that creates such precious particles is the “craftsmanship of the sharpening craftsmen” that has been passed down from master to disciple. Aiya Co., Ltd. employs these traditional craftsmen, who refine their skills every day to produce the highest quality fine particles.

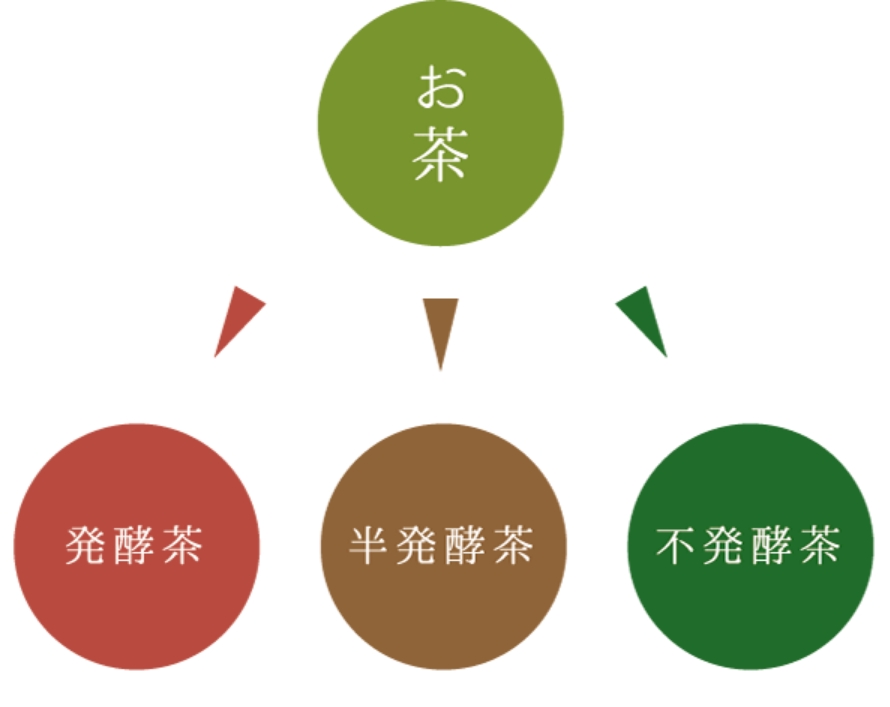

From one tea tree to various teas

Tea made by immediately steaming or roasting fresh leaves to inhibit fermentation enzymes and prevent fermentation is called “unfermented tea”, and green tea is a typical example.

Teas that are half-fermented are called semi-fermented teas, and oolong tea is a typical example.

Completely fermented tea is called fermented tea, and black tea is a typical example.

Aiya Co., Ltd., which was founded in 1888, offers a wide variety of high-quality green teas in addition to matcha, making use of the techniques cultivated through its history and tradition.

What they all have in common is the color of the tea leaves, “green”. We will introduce a variety of teas that allow you to enjoy the gentleness of this color with your eyes, taste it with your tongue, and feel its effects throughout your body.

Tencha is made by steaming the coated tea leaves before harvesting, drying them and refining them, then grinding them in a tea mortar into a powder. It is a superfood that allows you to fully absorb the rich nutrients of tea leaves.

This is the highest quality tea with a rich aroma and mellow sweetness. Extracting slowly with low-temperature water brings out the special flavor.

A well-balanced daily tea where you can enjoy all of the flavor, sweetness, astringency, bitterness, and aroma of green tea. It has a refreshing aroma and a mellow sweetness.

This is a tea made from roasted bancha. The tea leaves are brown. It has a refreshing taste with little bitterness or astringency. Recommended for children and those who are sick.

This tea is a blend of sencha and brown rice (made using domestically produced glutinous rice). It is fragrant and rich, and if you brew it all at once with boiling water, you can enjoy the aroma and refreshing taste.

Tea whose stems are sorted during the processing of matcha and gyokuro. It has a sweet taste similar to Gyokuro and a unique stem flavor. It can be easily brewed even with hot water.

PageTop

PageTop